Share 5 characteristics and technology of PVC printing film

2024-04-03 18:01The product features of PVC printing film are:

1. PVC printing film has a large shrinkage rate, and can tightly wrap articles after thermal shrinkage. If the PE straight-through bag (with openings at both ends of the bag) is made after thermal shrinkage, the articles can be lifted at both ends of the opening, which can accept 15KG weight and is convenient to carry.

Second, PVC printed film has good flexibility, is not easy to be damaged, has strong explosion resistance, strong impact resistance, strong tear resistance and strong tensile force, and can replace box packaging.

Third, PVC printed film is nontoxic, tasteless and pollution-free, which is an environmentally friendly packaging material.

4. PVC printed film is waterproof and dustproof, which can not only achieve the function of packaging, but also beautiful products and maintenance products.

Fifth, the PVC printed film has good brightness and light transmittance, which can display products and publicize products invisibly, and also reduce the distribution faults in the logistics link.

PVC printing film is widely used in the outer packaging of beer, drinks, building materials, food, tableware, cultural and sports goods, craft gifts, printed matter, etc. It can not only achieve the functions of dust prevention, anti-theft and transparent display of goods, but also increase the attractiveness of products. It can also be used to replace all kinds of cartons, which not only saves packaging costs, but also conforms to the packaging trend.

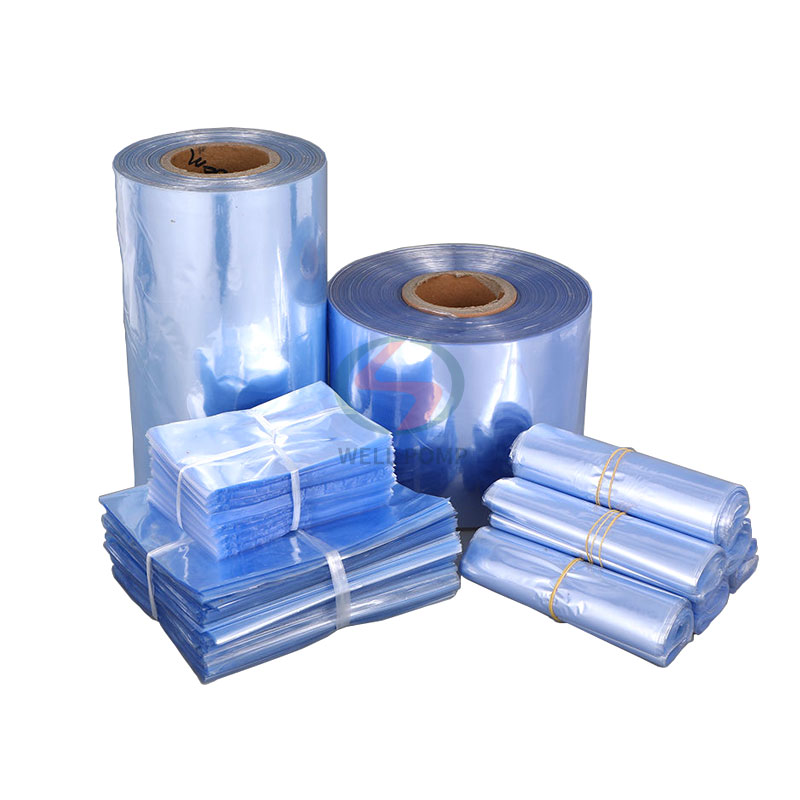

PVC printing film can be processed into: flat pocket, arc bag, tube bag, etc.

PVC printing film can assemble parts into a whole, and is also suitable for packaging single products. Because PVC printing film is a kind of thermoplastic plastic film which is stretched and oriented in the production process and shrunk by heat in the use process. Therefore, no matter which printing method is used for printing, the horizontal and vertical shrinkage of the material and the allowable deformation errors in all directions after shrinkage should be considered before the design of the surface pattern, so as to ensure the accurate reduction of the patterns, characters and barcodes shrunk to the container.

The food industry is a big market for heat-shrinkable packaging. The initial investment of gravure printing is high, but gravure printing plate is not afraid of high printing power, and its relative cost has become the main choice for PVC printing film printing. Moreover, the graphic part on the printing plate is concave, so a solid ink layer, bright colors and rich layers can be obtained.

Key points of production technology of PVC printing film;

First, if there are more heat stabilizers, the temperature of thermal melting activity will be improved;

2. PVC products with plasticizer dosage of 10 ~ 40 phr are called semi-hard products; PVC products with plasticizer content exceeding 40PHR are called soft products.

Third, in order to improve the melt processability of PVC, PVC formula can be melt processability, and processing AIDS should be added to PVC formula;

Four, PVC printed film products are different from soft and hard. In general, PVC products with plasticizer content below 10PHR in the formula are called hard products;

5. PVC is a heat-sensitive plastic, so there must be no heat stabilizer in the formula. In general PVC formula, the amount of heat stabilizer is 5 ~ 8 phr. If the heat stabilizer is less, it is not enough to prevent PVC from differentiating at the temperature of hot melt molding.

PVC printed films can be seen everywhere in life:

First, the PVC printing film has good performance, good strength and can bear the weight of the contents. Printing belongs to film printing (the picture and text are in the film sleeve), which can protect the imprint and the label performance is good. The heat shrinkable packaging technology and equipment are simple, and the heat sealability is good, and no adhesive is needed when labeling.

Second, nowadays, beverage containers have special shapes and more individual designs, and heat shrinkable film labels can clearly show the outline of the outer surface of beverage containers. Heat shrinkable film is close to the goods and has compact packaging, which can be applied to the packaging of irregular goods; Heat shrinkable film, as a label, saves forest resources, reduces costs, is sanitary and convenient to use.

Third, the transparency of PVC printed film is good, so the label has bright color and good luster. It can be produced on a large scale and is a label based on product production. After shrinking, heat shrinkable film clings to the goods, and the packaging is compact and can show the appearance of the goods, and the packaged goods are beautiful.