PVC heat shrinkable film as a New Packaging Material

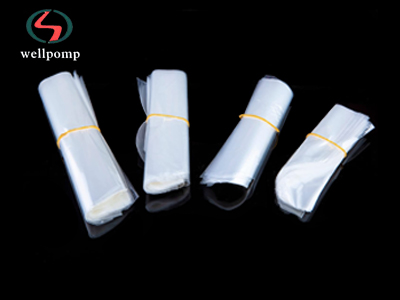

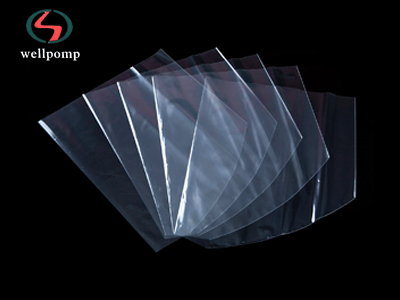

2023-09-15 11:53PVC heat shrinkable film is a new packaging material at present, which has good transparency, good toughness, no fear of impact and low water vapor transmission. There is also an ideal shrinkage rate. When the film is exposed to some temperature, it automatically shrinks and tightly wraps the goods, thus protecting the goods, and also playing the roles of rust prevention, pollution prevention, pre-injury prevention and theft prevention. Commodity storage stability, simple packaging technology and equipment, easy to realize automatic shrink packaging. PVC heat shrinkable film is used for the sales and transportation of various products, and its main function is to stabilize, cover and protect the products. Shrinkage film should have good puncture resistance, good shrinkage and corresponding shrinkage stress. In the process of shrinkage, the film can't produce holes. Because pvc heat shrinkable film is often used outdoors, it is necessary to add UV-resistant agent.

PVC heat shrinkable film has the characteristics of good transparency, good toughness, impact resistance, corrosion resistance and low water vapor permeability. When the film is exposed to some temperature, it automatically shrinks and tightly wraps the goods, thus achieving the functions of protecting the goods, rust prevention, pollution prevention, breakage prevention and theft prevention. The stability of commodity storage and transportation is good, and the packaging technology and equipment are simple, which is convenient for automatic heat-shrinkable packaging.

PVC is easy to break when printed in heat shrinkable film. It is not that the quality of PVC heat shrinkable film is not good, but that there is a solvent in the printing ink for PVC that will dissolve the PVC film, and the volatility of this solvent is small. Therefore, if there is too much solvent in the solvent for dissolving PVC in PVC ink, the PVC heat shrinkable film will be dissolved and broken during printing. However, if the printing ink for PVC is not used, the printing fastness is not good.

PVC heat shrinkable film can assemble the scattered goods into a whole, and it is also suitable for the packaging of single goods. Secondly, PVC heat shrinkable film clings to the surface of the package, which makes people feel sticky and makes the goods more beautiful, crisp and shiny. It is a wise choice to improve the competitiveness of goods. The important point is that PVC has low input and high output, which is why many businesses choose it. The surface protection of high-shielding products forms a light and shielding surface around the products, thus achieving the goals of dust prevention, water resistance and theft prevention. It is particularly important to compress the film packaging to make the packaged goods evenly stressed and prevent the uneven stress from harming the goods, which cannot be done by the traditional packaging methods (bundling, packaging, tape packaging, etc.).

Shrinkage film can present more and more beautiful effect and stronger functionality. With the improvement of quality of life and the diversification of packaging film, the requirements for shrinkage film are getting higher and higher. heat shrinkable film is used for the sales and transportation of various products, and its main function is to stabilize, cover and protect products. Shrinkage film must have good puncture resistance, good shrinkage and corresponding shrinkage stress. During the shrinkage process, the film cannot produce holes, because shrinkage film is often applicable. Therefore, it is necessary to add UV anti-ultraviolet agent, which has good flexibility, not easy to be damaged, strong blasting resistance, good impact resistance, good tear resistance and strong tensile force, can replace box packaging, has a large shrinkage rate, and can tightly wrap articles after thermal shrinkage. If the PE straight-through bag (with openings at both ends) is made after thermal shrinkage, the articles can be lifted at both ends of the opening, which can bear the weight of 15KG and is convenient to carry. Good transparency, light transmittance of 80%, can display products, can promote products invisibly, and also reduce distribution errors in logistics links. Not afraid of water and dust, it can not only achieve packaging effect, but also beautify and protect products.

PVC heat shrinkable film can be divided into soft PVC and hard PVC. Among them, hard PVC accounts for about 2/3 of the market and soft PVC accounts for 1/3.

Simply put, the aqueous solution of salt is chemically decomposed under the action of electric current. This process produces chlorine, caustic soda and hydrogen. Refining and cracking petroleum or gasoline can produce ethylene. When chlorine and ethylene are mixed, dichloroethylene will be produced; Dichloroethylene can be converted into chlorinated vinyl, which is the basic component of PVC. During the polymerization process, chlorinated vinyl molecules are connected together to form PVC chains. The PVC produced in this way is white powder. It can't be used alone, but it can be mixed with other ingredients to produce many products.

Vinyl chloride was first synthesized in the laboratory. And PVC was synthesized in 1872. PVC has the advantages of (value over 40), no fear of chemicals (concentrated hydrochloric acid, 90% sulfuric acid, 60% nitric acid and 20% sodium hydroxide), good mechanical strength and electrical insulation. However, it is not afraid of poor heat resistance, its softening point is 80℃, and it begins to decompose and change color at 130℃, and HCI is precipitated.