Thermosetting characteristics of heat shrinkable packaging film

2023-09-08 18:18Introduction to the characteristics of thermosetting plastics in the production of heat shrinkable packaging film

1. The material can be made of all kinds of suitable fiber or rubber fillers and some toughening agents, if necessary in an earthquake. In addition, aniline modified phenolic resin, epoxy resin, polyvinyl chloride, polyamide and polyvinyl acetal can also be used to meet the requirements of different uses. Phenolic laminate can also be made of phenolic resin, which has the characteristics of good mechanical and electrical properties, corrosion and easy processing, and is widely used in low-voltage electrical equipment.

2. Amino heat shrinkable packaging films include urea formaldehyde, melamine formaldehyde and urea melamine formaldehyde. They have the advantages of hard texture, scratch resistance, colorless and translucent, and colored materials can be made into colorful products. Because it is not afraid of oil, weak alkali and solvent (but not acid), it has good acid resistance.

3. Thermosetting plastics made of phenolic resin as the main raw material, such as phenolic molded heat-shrinkable packaging film, have the characteristics of strong durability, stable size and no fear of other chemicals except strong alkali. Various fillers and additives can be added according to different purposes and requirements. If the insulation performance requirements are good, mica or glass fiber can be used as filler; For varieties not afraid of heat, asbestos or other fillers not afraid of heat can be used.

4. Thermosetting heat shrinkable packaging film refers to plastics that can be cured or have insolubility under heating or other conditions, such as phenolic plastics and epoxy plastics. Thermosetting plastics can be divided into formaldehyde crosslinking type and other crosslinking types. Resin molecules are crosslinked into a network structure through linear structure. Further heat will decompose. Typical thermosetting plastics include phenolic resin, epoxy resin, amino group, unsaturated polyester, furan and polysilane, as well as new plastics such as polypropylene phthalate. They have the advantages of high heat resistance and not easy to deform when heated. The disadvantage is that the mechanical strength is generally not high, but it can be improved by adding fillers, laminates or molding materials.

What aspects should be paid attention to in the production of heat shrinkable packaging film?

1. From the consumer's point of view, simple and clear label information will increase their trust in products, and they hope that food manufacturers can convey what they want to know to consumers through labels. According to the survey, 58% of customers will check the ingredient information, while more than three quarters are worried about using artificial agents.

2. Nowadays, many consumers pay attention to product information. When they buy products, they need to know important information such as nutritional components and functions, so that they can decide whether to buy products. Therefore, the labels of packaging bags should show these important information simply and clearly.

3. Sight, touch, smell, taste and hearing can all attract consumers. Many manufacturers often put the visual element in front when considering the elements of packaging bags to attract consumers. However, it means that touch can mobilize people's senses, and touch can make consumers more willing to pay higher prices.

4. The method of increasing the sense of touch can use embossing, laser etching and other methods in printing. Although this will increase the time and cost of packaging bag production, these additional investments will help the product gain additional value. These special effects on the packaging bag can attract more attention from consumers.

Heat shrinkable packaging film uses far infrared radiation to directly heat films of various specifications. The products are transported to the shrinkage furnace by conveyor belt, and the products are packed with shrink packaging film, sealed and then enter the shrink packaging machine, and the products automatically shrink. The power consumption of heat-shrinkable packaging machine is small, and the average hourly power consumption is only 2.1KW, which achieves the correct shrink packaging effect, and will never affect the packaging. The electronic stepless speed change, the solid-state voltage regulator controls the temperature and is stable, and it is applied to the heat shrinkage of food, beverage, candy, stationery, hardware tools, daily necessities, chemical products, etc.

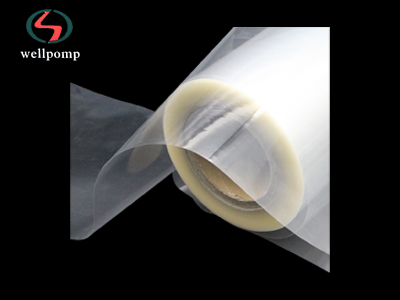

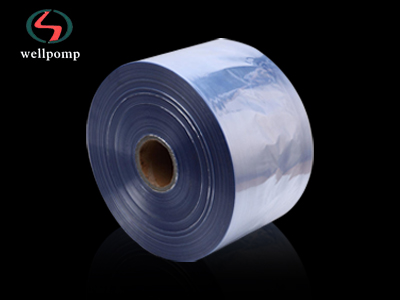

Heat shrinkable packaging film needs to have good puncture resistance, good shrinkage and corresponding shrinkage stress. In the process of shrinkage, the film cannot produce holes. Since heat-shrinkable packaging films are often suitable for outdoor use, it is necessary to add UV anti-ultraviolet agents. It has good flexibility, not easy to be damaged, strong blasting resistance, good impact resistance, good tear resistance and strong tensile force, and can replace box packaging.

The shrinkage rate is large, and the articles can be tightly wrapped after thermal shrinkage. If the PE straight-through bag (with openings at both ends) is made after thermal shrinkage, the articles can be lifted at both ends of the opening, which can bear the weight of 15KG and is convenient to carry. Good transparency, light transmittance of 80%, can display products, can promote products invisibly, and also reduce distribution errors in logistics links. It is waterproof and dustproof, which can not only achieve the packaging effect, but also beautify and protect the products.

The application of heat shrinkable packaging film in the domestic market mainly shows the following characteristics:

1. It has been widely used in fast food, ceramic products, tea sets, mechanical parts and other areas;

2, it is used for labeling various bottled beer and beverages, which can reduce the process of removing labels and facilitate recycling;

3. It is of great significance to apply the combination of heat-shrinkable film and gas-phase antirust technology to replace antirust oil in machinery and hardware tools to enhance the antirust ability;

4. Heat shrinkable film is also the patron saint of building and transportation materials. It is not only suitable for the packaging of multiple products and packaging with pallets, but also convenient for transportation and sales, easy to realize mechanization and save labor and material resources, and can partially replace the packaging of cartons and wooden cases;

5, used for bottled beer packaging instead of tying rope.