Application and main performance of heat shrinkable film characteristics

2023-12-16 16:23Shrinkage film (bag) can be processed into flat pocket, arc-shaped bag, trapezoidal bag, three-dimensional bag and other special-shaped bags. Heat shrinkable film is mainly made by mixing and extruding several different brands of poly (vinyl chloride) resins, which has the properties of puncture resistance and good quality. The goods stacked on pallets are wrapped and packed, which makes the packages stable and tidy, and is not afraid of water. It is widely used in foreign trade import and export, paper making, hardware, plastic chemical industry and building materials industries.

Heat shrinkable film product characteristics application:

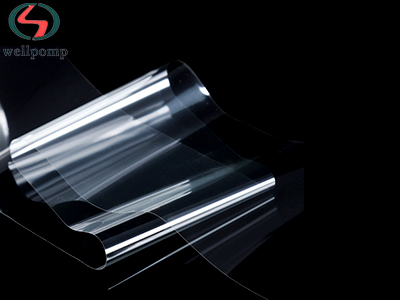

1. Good transparency, uniform thickness and good flatness.

2. The thickness can be customized according to requirements: 0.15-0.08mm;; Width 30-1200mm.

3, the relative cost is ok, and it is the material for the general packaging of the product.

4, easy to shrink at low temperature, and the shrinkage rate can be adjusted freely according to the needs of customers' products.

5. It is made of global raw materials by formula blown film.

6. Can produce tube material and open edge material according to different requirements, and can also make bags according to requirements: flat-mouth, arc-shaped, corner-cut and other special-shaped bags.

Heat shrinkable film is used for the sale and transportation of various products, and its main function is to stabilize, cover and protect products. Shrinkage film should have good puncture resistance, good shrinkage and corresponding shrinkage stress. In the process of shrinkage, the film cannot produce holes. Since the shrink film is often suitable for outdoor use, it is necessary to add UV anti-ultraviolet agent.

Heat shrinkable film needs to have good puncture resistance, good shrinkage and corresponding shrinkage stress. In the process of shrinkage, the film cannot produce holes. Since the shrink film is often suitable for outdoor use, it is necessary to add UV anti-ultraviolet agent. Includes OPS/PE/PVC/POF/PET shrink film.

1. PVC film has the characteristics of high transparency, good gloss and good shrinkage.

2. PE heat shrinkable film is generally suitable for the whole package of wine, cans, mineral water, various beverages, cloth and other products. The product has good flexibility, strong impact resistance and tear resistance, and is not easy to be damaged, not afraid of moisture and has a large shrinkage rate;

3. The ops shrink film (oriented polystyrene) heat-shrinkable film is a new type of packaging material with OPS heat shrinkable film, which meets the requirements of environmental protection. The OPS heat-shrinkable film has good strength, high rigidity, stable shape, and good gloss and transparency. Convenient processing, easy coloring, good printing performance and high printing resolution, which is all a material progress for trademarks that are constantly pursuing exquisite printing. Because of the high shrinkage and strength of OPS film, it can closely fit with containers of different shapes, so it can not only print exquisite patterns, but also achieve the use of novel packaging containers with different shapes. This clean and tasteless film, which is not afraid of grease, can allow designers to adopt eye-catching colors, realize 360 label design, and give full play to creativity and imagination, thus making the patterns of drinks and other commodities more vivid in label use.

4. POF has the characteristics of high surface gloss, good toughness, high tear strength, uniform thermal shrinkage and is suitable for automatic packaging, and it is the replacement product of old-fashioned PVC heat shrinkable film. POF means heat shrinkable film, and POF is the full name of multi-layer coextruded polyolefin heat shrinkable film. It is made of linear polyethylene as the middle layer (LLDPE) and polypropylene (pp) as the inner and outer layers, plasticized and extruded by three extruders, and then processed by special processes such as die forming and film bubble inflation.

In heat shrinkable film, far infrared radiation is used to directly heat films of various specifications. The products are transported to the shrinking furnace by conveyor belt, and the products are packed with shrink packaging films, sealed and then enter the shrink packaging machine, and the products automatically shrink. The power consumption of heat-shrinkable packaging machine is small, and the average hourly power consumption is only 2.1KW, which achieves the correct shrink packaging effect, and will never affect the packaging. The electronic stepless speed change, the solid-state voltage regulator controls the temperature and is stable, and it is applied to the heat shrinkage of food, beverage, candy, stationery, hardware tools, daily necessities, chemical products, etc.

At present, the application of heat shrinkable film in the domestic market mainly shows the following characteristics:

1. It has been widely used in fast food, ceramic products, tea sets, mechanical parts and other areas;

2. It is of great significance to apply the combination of heat-shrinkable film and gas-phase antirust technology to replace antirust oil in machinery and hardware tools to enhance antirust ability;

3. It can be used for labels of various bottled beer and beverages, which can reduce the process of removing labels and facilitate recycling;

4, used for bottled beer instead of tying rope packaging to prevent bottled beer from hurting people;

5. Heat shrinkable film is also the patron saint of building and transportation materials. It is not only suitable for the packaging of multiple products and packaging with pallets, but also convenient for transportation and sales, easy to realize mechanization and save labor and material resources, and can partially replace the packaging of cartons and wooden cases.