Production performance of heat shrinkable film application

2023-12-01 17:28Heat shrinkable film's widely used performance advantages We have summarized the following aspects:

1. The packaging cost is ok, and it is good.

2, good flexibility: to avoid the impact of external forces on the packaged items, and to protect the packaged items.

3. Strong resistance to cold: even at minus 50 degrees Celsius, its physical properties will not change, so it is suitable for the packaging and transportation of frozen food.

4. The shrinkage rate is good: heat shrinkable film has a good shrinkage rate of 75%, which is suitable for the collective packaging of multiple items and convenient transportation. And can meet the requirements of different commodities for contractility.

5. No harm: the materials used in heat shrinkable film are harmless, and they are green packaging materials that are rarely certified by the United States.

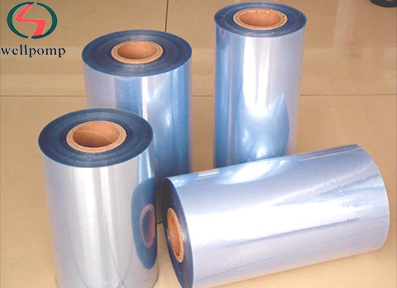

Heat shrinkable film can package different kinds of products, and the heavy metals do not exceed the standard, which is characterized by relatively low shrinkage temperature and slow thermal shrinkage speed, and generally can achieve excellent results at 80-120 degrees. The product has high transparency, clarity and strong gloss.

Instant heating and easy shrinkage are suitable for all types of shrinking machines, which are widely used and suitable for low-cost and low-cost product packaging. Such as: wood products, craft gifts, candles, brochures, printed matter, electronic appliances and other industries. At the same time, it can be made into various flat pocket, arc bag, special-shaped bag and triangle bag. Tight packaging, beautiful and generous. Printing does not fade. Heat shrinkable film can be used for insulating packaging of electrical appliances and electronic components (such as the outer packaging of dry batteries); Packaging of general goods and packaging of food contact. Using it as packaging material can not only simplify the packaging process and reduce the packaging volume, but also show the color and shape of the packaged goods clearly because of the shrink transparent film, so heat shrinkable film is widely used in commodity packaging.

We should have a basic understanding of shrink film, so there should be other questions about why shrink film should be added to the function of not being afraid of ultraviolet rays. Shrink film is used in the sale and transportation of various commodities. Its main function is to stabilize, cover and maintain commodities. Shrinkage film should have good puncture resistance, outstanding shrinkage and corresponding shortening stress, and the film should not have holes. Because the shrink film is often suitable for outdoor use, it is necessary to participate in UV anti-ultraviolet agents to achieve the function of packaging shrinkage without fear of ultraviolet rays.

What aspects should be paid attention to in the production of heat shrinkable packaging film?

1. From the consumer's point of view, simple and clear label information will increase their trust in products, and they hope that food manufacturers can convey what they want to know to consumers through labels. According to the survey, 58% of customers will check the ingredient information, while more than three quarters are worried about using artificial agents.

2. Nowadays, many consumers pay attention to product information. When they buy products, they need to know important information such as nutritional components and functions, so that they can decide whether to buy products. Therefore, the labels of packaging bags should show these important information simply and clearly.

3. Sight, touch, smell, taste and hearing can all attract consumers. Many manufacturers often put the visual element in front when considering the elements of packaging bags to attract consumers. However, it means that touch can mobilize people's senses, and touch can make consumers more willing to pay higher prices.

4. The method of increasing the sense of touch can use embossing, laser etching and other methods in printing. Although this will increase the time and cost of packaging bag production, these additional investments will help the product gain additional value. These special effects on the packaging bag can attract more attention from consumers.

Heat shrinkable film LLDPE stretch-wound film is made by adding tackifier, heating, extruding, casting and cooling by chilling roller. It has the advantages of strong toughness, tear resistance, high viscosity, thin thickness, no fear of cold, heat, pressure, dust, water, single-sided adhesion and double-sided adhesion.

When in use, it can save materials, labor and time, and is widely used in papermaking, logistics, chemical industry, plastic raw materials, building materials, food, glass and so on.