Manufacturers share the classification and characteristics of shrink film

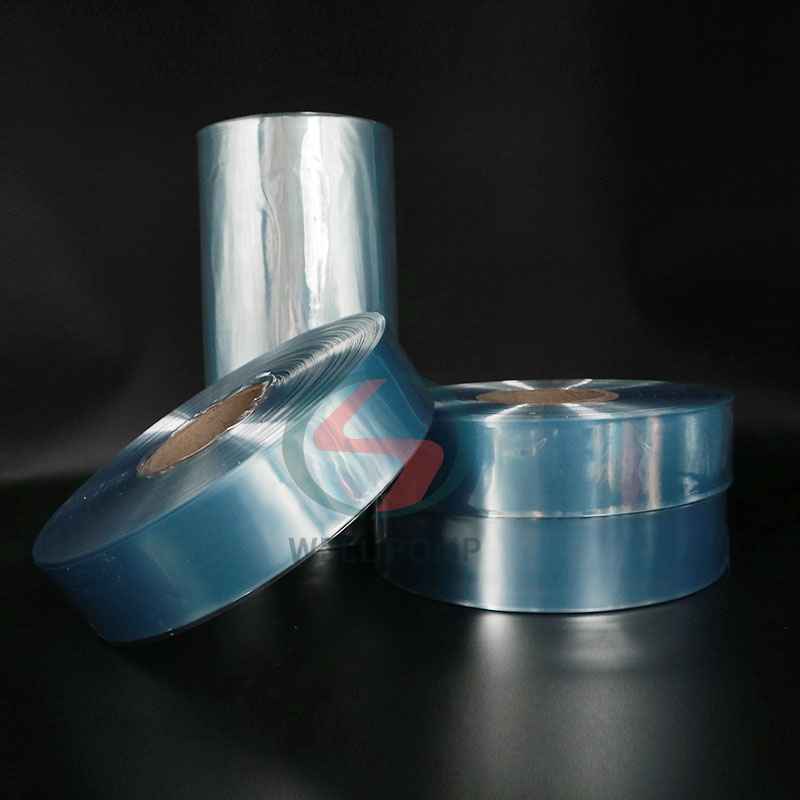

Shrink film is a common packaging film. In packaging applications, heat shrinkage is often used to achieve mounting or wrapping effects. At the same time, it is also used to protect the contents from contamination or damage. Shrink film can be divided into four categories (PVC shrink film, PE shrink film, POF shrink film and Other shrink films) according to different raw materials and processes.

Characteristics of PVC shrink film

PVC shrink film is one of the longest shrink films in history. It is produced by the double bubble process of secondary expansion of polyvinyl chloride. PVC shrink film has the characteristics of high transparency, high stiffness and low shrinkage temperature. In recent years, in the field of display packaging, POF shrink film has occupied a large part of the PVC shrink film market. But in the shrink bottle label market, PVC shrink film still occupies most of the market share due to its low cost, high shrinkage rate and easy printing. However, due to the generation of harmful insect gas during the processing, its use is increasingly restricted by environmental protection requirements.

2.Characteristics of PE shrink film

PE shrink film is another shrink film with a long history. As the name implies, PE shrink film is a heat-shrinkable film made of polyethylene. Unlike PVC shrink film, PE shrink film is produced by ordinary blown film process. Due to the high processing temperature (far exceeding the melting point of polyethylene), low-density polyethylene with a large number of long-chain branches is generally used as the production raw material. In this way, a film with sufficient shrinkage can be obtained. In recent years, with the development of catalyst technology and polymerization technology, some new metallocene polyethylene and linear low-density polyethylene can provide excellent mechanical properties as well as good shrinkage. As a result, a large number of highly transparent and high-strength PE shrink films have appeared on the market.

3.Characteristics of POF shrink film

POF shrink film has developed rapidly in recent years. Ordinary POF shrink film is a three-layer co-extrusion structure, with the surface layer being ter-PP and the core layer being LLDPE. Similar to PVC shrink film, POF shrink film is produced using the double-bubble method. Since the second layer of film bubbles is not easy to stabilize, the requirements for linear low-density polyethylene in the formula are very high. Cross-linked film is a high-end product among POF shrink films. Unlike ordinary POF films, cross-linked film is a pure PE structure. The production process is also slightly different from the common double-bubble method. It needs to be supplemented by an electron irradiation cross-linking process to change the structure of the polymer chain from a linear structure to a body structure. Compared with ordinary POF film, cross-linked film has better shrinkage and heat sealing properties and can adapt to different packaging machinery and contents.