Matters needing attention and universality of packaging film storage

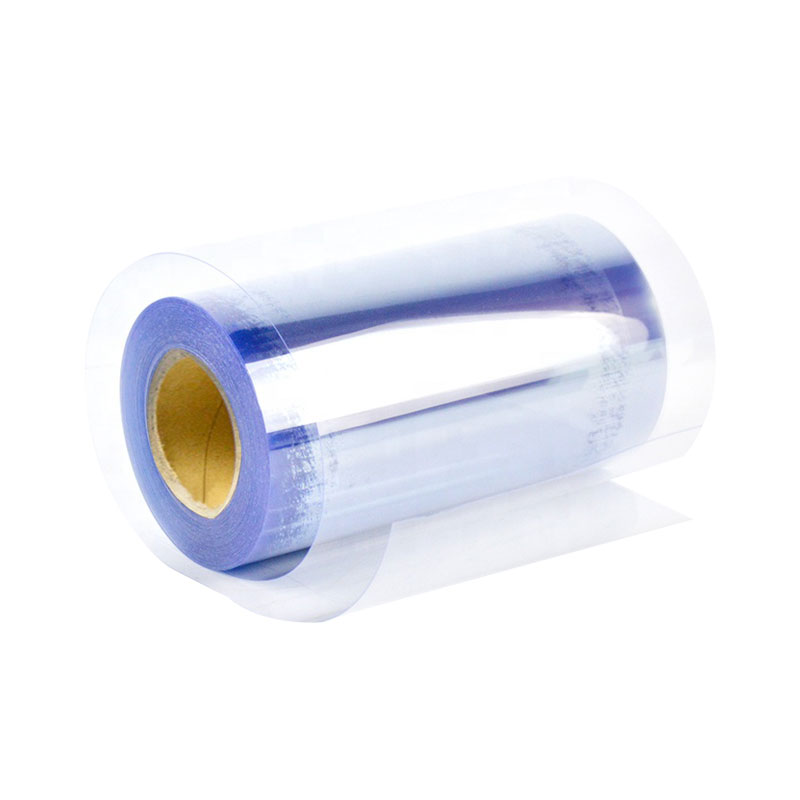

2024-03-10 16:29Packaging film is mainly used for winding packaging of products and goods, which can make the packaged goods more stable and stable. Just like this, this product has been widely used in various industries, especially in the building materials industry. So, have you considered how to store the unused products?

What should be paid attention to when packaging film products are stored?

1. When storing the product, avoid the sun and rain, and suggest that you roll it up and save it when not in use, otherwise it will affect the later use of the product.

Second, we store the product because we don't use it, but if we don't use it for a long time, I suggest you turn it over once every once in a while to prevent the product from sticking together.

Third, the manufacturer of the product reminds everyone that when storing the bag, it should be placed in rolls, and the packaging film should not be folded, and the temperature of the place where the product is stored should not be too high or too low.

The above are the points for attention when storing packaging films, for example, do not expose to the sun or rain, and the storage temperature should not be too high or too low, otherwise these will have a corresponding impact on its quality. In addition, it should be turned once in a while to prevent it from sticking together and affecting its use.

The packaging film has puncture resistance and good performance. The goods stacked on the pallet are wound and packaged, which makes the packaging more stable and tidy, so it is widely used. Recently, some customers called to know how the packaging film is. At the request of our customers, the packaging film manufacturers will tell you how the packaging film is. Take a look if you are interested.

Packaging film is suitable for packaging various shapes of goods, so it increases the attractiveness of products, and the packaging film can be close to the goods, with transparency and beautiful appearance. The main thing is that the packaging film can protect the packaged goods well, making the packaged goods hygienic, clean, sealed, dustproof and moisture-proof. Many customers complain that some products packaged with packaging film are not, but the packaging film produced by packaging film manufacturers can tightly wrap the packaged goods together, and small parts will not be packaged. We are a packaging film manufacturer. Over the past few years, the packaging films produced by our company have been widely favored by people. Because the packaging films produced by the packaging film manufacturers have met the needs of our customers and the quality is certain, we have made a lot of gains in the packaging industry.

Well, that's what the packaging film manufacturers have brought. I hope it will help you. If you trust our products, you are welcome to come to our company to discuss business. We are willing to make progress together with our customers.

Food packaging film can protect food, protect the freshness of food, and prevent dust from affecting food sales. Therefore, it can be seen that packaging film is still very important and indispensable in our daily use, which can not only be insured, but also avoid cross-smell. So here is a detailed introduction to the knowledge of packaging film:

First, protect the appearance quality of food and produce corresponding economic benefits.

Second, food packaging film can protect food and extend the shelf life of food, which is mainly reflected in:

Third, protect the original quality of food and extend the shelf life of food.

In addition, food packaging film can facilitate circulation, prevent food from deteriorating and squeezing during transportation, and prevent dust from falling in. It is an indispensable food packaging tool in present life.

The packaging film is mainly made of several different resins, which has the performance of puncture resistance. We have introduced several different types of packaging films before, and now the packaging film manufacturers will introduce the general properties of packaging films for you. Please see the following:

1. Cost saving: Using wound packaging film to package products can reduce the use cost, labor intensity and improve the packaging speed.

Second, protection: the packaging film can protect the surface of the object, and the way of winding the packaging makes the packaged goods evenly stressed and not easy to be damaged.

Third, compression fixability: the products are wrapped by the retraction force after the winding film is stretched, forming a compact and space-free unit whole, which can prevent the products from being dislocated and moved during transportation.

As we all know, the advantages of packaging film can be adapted to packaging various shapes of goods, increasing the attractiveness of products, and the packaging film can be close to goods and has transparency. The packaging film manufacturer tells us that there are many micropores like capillaries in the structure of packaging film, which constitute channels for allowing vapor to pass through, but they cannot pass through because of the diameter of external liquid droplets. The permeability of vapor passing through packaging film depends on the size of micropores. In microporous packaging film, the physical structure of packaging film is permeability.

Packaging film has been widely used now, and it can be seen everywhere in our lives. The reason why packaging film is popular is that it can make the packaging more stable and tidy, and it is not afraid of water when using packaging film. Packaging film manufacturers take you to know the classification of packaging films and learn together.

First, casting polypropylene film

The cast polypropylene film is a polypropylene film produced by casting process, which can be divided into ordinary CPP and cooking grade CPP. The packaging film manufacturer reminds you that the cast polypropylene film has good transparency, uniform thickness and even vertical and horizontal performance.

Second, chlorinated polyethylene (CPE)

Chlorinated polyethylene (CPE) is a saturated polymer material with white powder appearance, which has excellent weather resistance, ozone resistance, aging resistance and good oil resistance.

Third, biaxially oriented polypropylene

Biaxially oriented polypropylene is made of polypropylene particles which are coextruded into sheets and then stretched in both vertical and horizontal directions.

Iv. Polyester film (PET)

Polyester film is a film material made of polyethylene terephthalate by extrusion and biaxial stretching.