Development prospects of POF heat shrink film

2025-05-13 16:43Shrink film is a thermoplastic film that is stretched and oriented during production and shrinks when heated during use. The heat shrinkability of film was first used as early as 1936, and was initially used to shrink perishable foods with rubber film. Today, heat shrink technology has developed to the point where almost all goods can be packaged with plastic shrink film. In addition, shrink packaging is also used to make shrink labels and shrink bottle caps, so that containers that are difficult to print or have complex shapes can be labeled. Recently, newer application areas have been developed.

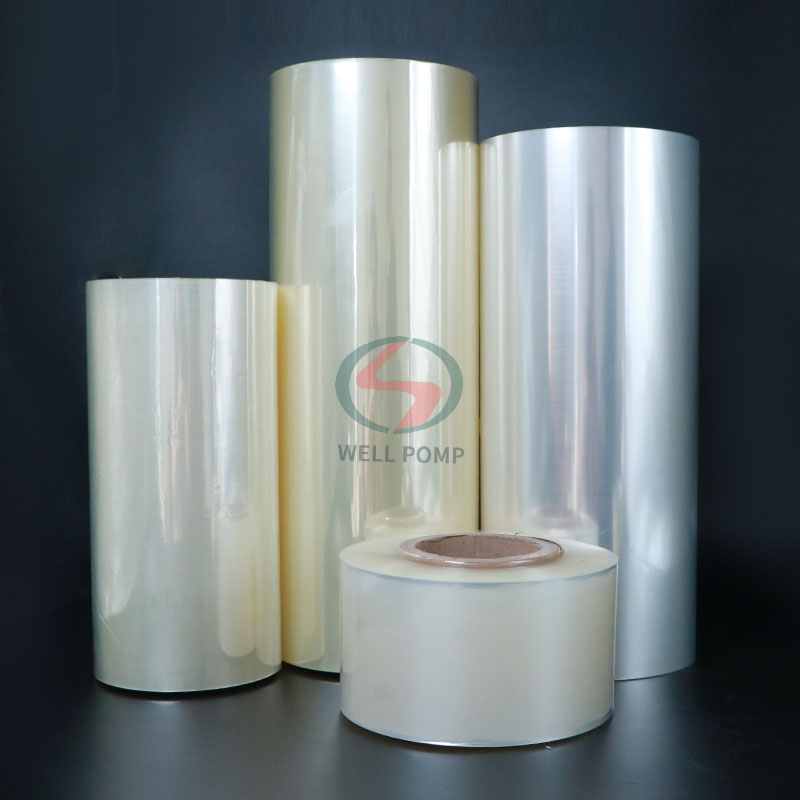

Production technology and characteristics: Shrink film is usually produced by extrusion blow molding or extrusion casting to produce thick film, and then stretched longitudinally and transversely at a high elastic temperature above the softening temperature and below the melting temperature, or stretched and oriented in one direction only, and not stretched in the other direction. The former is called biaxial stretch shrink film, and the latter is called unidirectional shrink film. When in use, the packaged goods can be wrapped by the shrinkage force when it is greater than the stretching temperature or close to the stretching temperature. Shrink packaging has the following advantages:

(1) It has a beautiful appearance and fits closely to the product, so it is also called skin packaging, which is suitable for packaging products of various shapes;

(2) It has good protection. If the inner packaging of the shrink packaging is combined with the transport packaging hung on the outer packaging, it can have better protection;

(3) It has good cleanliness, especially suitable for packaging precision instruments and high-precision electronic components;

(4) It has good economic efficiency;

(5) It has good anti-theft performance. Multiple foods can be packaged together with a large shrink film to avoid loss;

(6) Good stability, the product will not fall over in the packaging film;

(7) Good transparency, customers can directly see the content of the product.

Market development and typical applications The materials used for heat shrink film are mainly various thermoplastic films. Initially, PVC shrink film was the main one. With the continuous development of market demand, PVC shrink film gradually decreased, while various PE, PP, POF and other multi-layer co-extruded heat shrink films developed rapidly and became the mainstream of the market.The market is expanding further. According to experts' prediction, the domestic heat shrink film market will grow at a rate of more than 20%. The food industry is the largest market for heat shrink packaging. Heat shrink films are widely used in the packaging of various fast food, lactic acid food, beverages, snacks, beer cans, various alcoholic beverages, agricultural and sideline products, dry food, local specialties, etc. The application in non-food fields is also increasing, such as labels and bottle caps, seals, fibers and clothing, aerosol products, sporting goods, electrical products, cosmetics, pharmaceuticals, grease, detergents, stationery, toys, office supplies, kitchen supplies, daily necessities, sundries, building materials, etc.At present, the application of heat shrinkable film in the domestic market mainly shows the following characteristics:

(1) It has been widely used in fast food, ceramic products, tea sets, mechanical parts and other fields;

(2) The method of combining heat shrinkable film with vapor phase rust prevention technology to replace anti-rust oil in military machinery and hardware tools has enhanced the anti-rust ability, which is of great significance;

(3) Heat shrinkable film is also the guardian of construction and transportation materials.It is suitable for packaging multiple products and packaging with pallets, which is convenient for transportation and sales. It is easy to mechanize, saves labor and material resources, and can partially replace cardboard and wooden box packaging;

(4) It can be used for various PET bottled beer and beverage labels, which can reduce the process of removing labels and facilitate recycling and reuse;

(5) It can be used to replace the strapping rope packaging of bottled beer to prevent bottled beer from exploding and injuring people.When choosing heat shrink film, customers usually first consider the cost. Heat shrink packaging and laminating film can usually achieve the same packaging effect, so how to decide which packaging film to use? In general, the main differences lie in the requirements for packaging patterns, the frequency of packaging, the requirements for shelf life, and the physical properties of the packaging itself, such as liquid, powder, granular, solid, square, etc.The following criteria can help customers choose appropriate packaging materials: the size of the food plant; whether the service target is industrial system or retail industry; adjustment requirements; shelf life requirements; anti-abuse requirements; product shape; whether it is used for preservation, freezing or other environmental requirements; and the consistency between the packaging production company and the customer's culture.

The general retail industry requires consumers to be oriented to the needs of consumers, and pays more attention to the attractiveness of printing effects to consumers and the convenience of packaging. It is different for industrial packaging, which pays more attention to the uniqueness of the product and whether it is convenient for mass processing. In general, the choice of heat shrink packaging should consider the attractiveness of the packaging to consumers and good sealing safety. There are many corresponding technologies for the heat shrink film market and heat shrink film applications of special functional packaging. Looking at the development of domestic and foreign markets, low-temperature heat shrink technology, low-cost technology, multi-purpose adaptability, online packaging technology and high-reliability technology have become the general trend of heat shrink packaging research. It is the continuous promotion of various new technologies that the application field of heat shrink packaging is becoming wider and wider.