There are several requirements in the transportation process in heat shrinkable film.

2024-02-29 15:08Attention should be paid to the following aspects during transportation in heat shrinkable film: Avoid sun and rain. Make sure the package is complete. Stay away from heat sources. Prevent collision and extrusion.

Heat shrinkable film can present more and more beautiful effects and stronger functions. With the improvement of the quality of life and the diversification of packaging films, the requirements for shrink films are getting higher and higher. heat shrinkable film is used for the sales and transportation of various products, and its main function is to stabilize, cover and protect products.

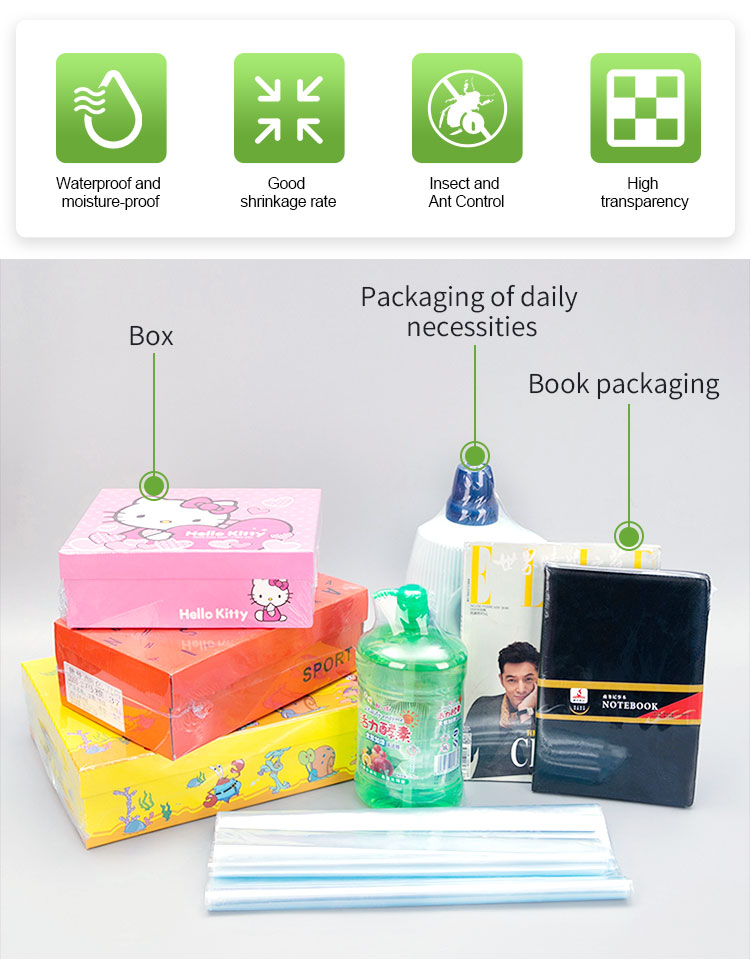

In the process of shrinkage, the film cannot produce holes. Because shrink film is often suitable for outdoor use, it is necessary to add UV agent. It has good flexibility, not easy to be damaged, strong blasting resistance, good impact resistance, good tear resistance and strong tensile force, and can replace box packaging. The shrinkage rate is large, and the articles can be tightly wrapped after thermal shrinkage. If the PE straight-through bag (with openings at both ends) is made after thermal shrinkage, the articles can be lifted at both ends of the opening, which can bear the weight of 15KG and is convenient to carry. Good transparency and light transmittance can display products, promote products indirectly, and reduce distribution errors in logistics links. Not afraid of water and dust, it can not only achieve packaging effect, but also beautify and protect products.

At present, the application of heat shrinkable film in the domestic market mainly shows the following characteristics:

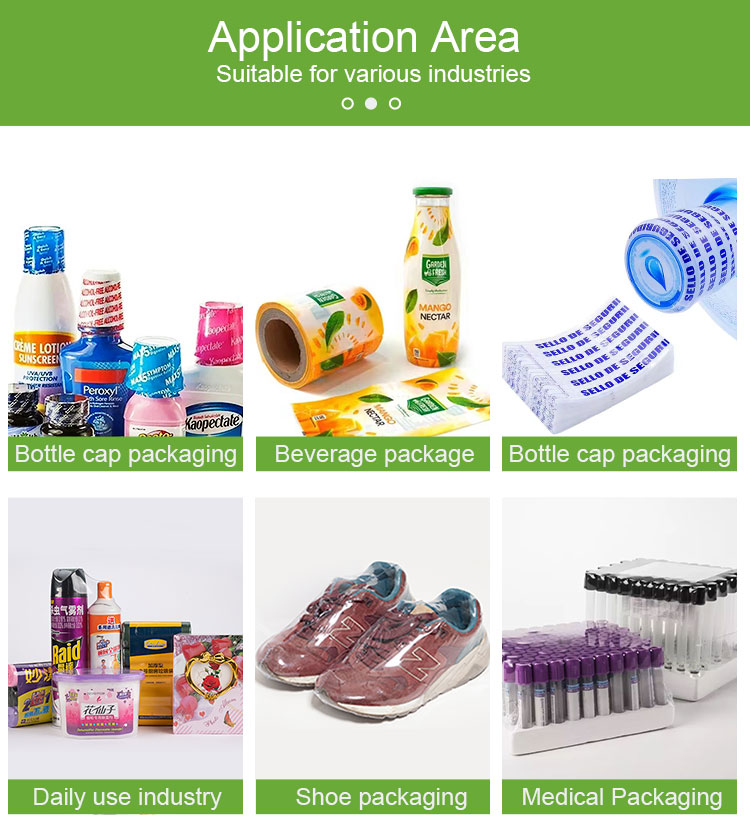

1. It has been widely used in fast food, ceramic products, tea sets, mechanical parts and other areas;

2, it is used for labeling various bottled beer and beverages, which can reduce the process of removing labels and facilitate recycling;

3. It is used for packaging bottled beer instead of tying rope;

4. It is of great significance to apply the combination of heat-shrinkable film and gas-phase antirust technology to replace antirust oil in machinery and hardware tools to enhance antirust ability;

5. Heat shrinkable film is also the patron saint of building and transportation materials. It is not only suitable for the packaging of multiple products and packaging with pallets, but also convenient for transportation and sales, easy to realize mechanization and save labor and material resources, and can partially replace the packaging of cartons and wooden cases;

Heat shrinkable film can be processed into: flat pocket, arc-shaped bag, tube bag, etc. In heat shrinkable film, far infrared radiation is used to directly heat films of various specifications. The products are transported to the shrinking furnace by conveyor belt, and the products are packed with shrink packaging films, sealed and then enter the shrink packaging machine, and the products automatically shrink. The power consumption of heat-shrinkable packaging machine is small, and the average hourly power consumption is only 2.1KW, which achieves the correct shrink packaging effect, and will never affect the packaging. The electronic stepless speed change, the solid-state voltage regulator controls the temperature and is stable, and it is applied to the heat shrinkage of food, beverage, candy, stationery, hardware tools, daily necessities, chemical products, etc.

Heat shrinkable film machine can assemble parts into a whole, and it is also suitable for single product packaging. Heat shrinkable film is a kind of thermoplastic film which is stretched and oriented in the production process, but shrinks when heated in the use process. Therefore, no matter which printing method is used for printing, the horizontal and vertical shrinkage of the material and the allowable deformation errors in all directions after shrinkage should be considered before the design of the surface pattern, so as to ensure the accurate reduction of the patterns, characters and barcodes shrunk to the container.

The food industry is a big market for heat-shrinkable packaging. The initial investment of gravure printing is high, but gravure printing plate is not afraid of high printing power, and it has become the main choice for printing in heat shrinkable film. Moreover, the graphic part on the printing plate is concave, so a solid ink layer, bright colors and rich layers can be obtained.