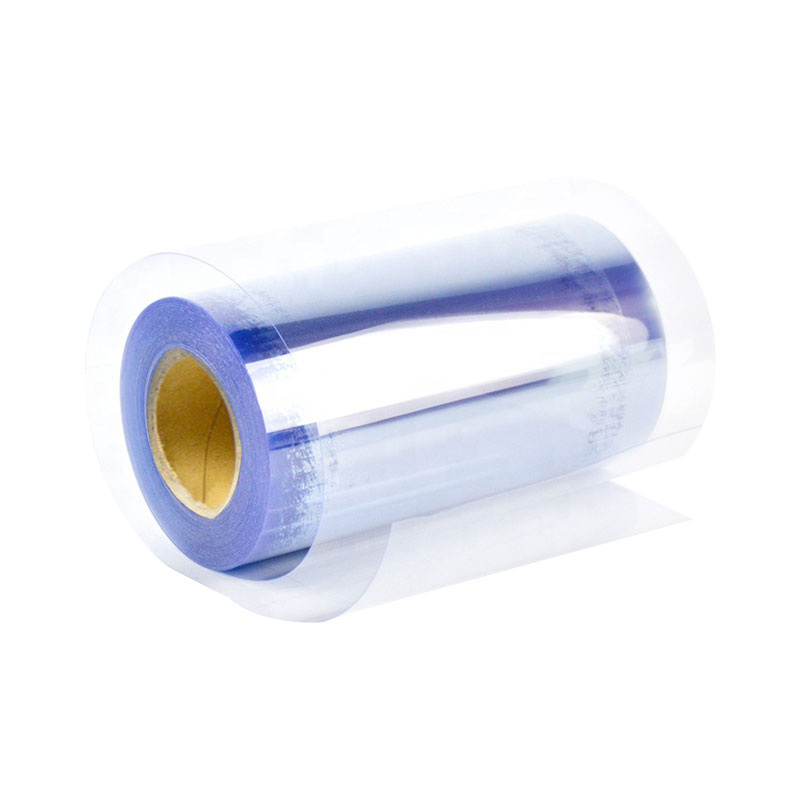

Summary of characteristics of pvc heat shrinkable printing film packaging box

2024-03-08 16:20Production principle of PVC heat shrinkable printing film The stable state of polymer chain tends to curl. When the polymer is in a high elastic state when it is heated and melted, the orientation of the polymer chain is stretched and straightened under the action of external force, and the orientation state of the polymer chain is frozen after it is cooled to the glass transition temperature.

When the temperature rises again, the polymer chain tends to be stable and curls, which is macroscopically manifested as contraction. According to its shrinkage principle, there is no chemical change, so it is called "physical reducibility". Using the above principle, the PVC heat-shrinkable printing film made by blow molding is made after two times of inflation and rapid cooling.

PVC heat shrinkable printing film is used for the sales and transportation of various products, and its main function is to stabilize, cover and protect the products. PVC heat shrinkable printing film needs to have good puncture resistance, good shrinkage and corresponding shrinkage stress. In the process of shrinkage, the film cannot produce holes. Because PVC heat shrinkable printing film is often suitable for outdoor use, it is necessary to add UV anti-ultraviolet agent.

Shrinkage film should have good puncture resistance, good shrinkage and corresponding shrinkage stress. In the process of shrinkage, the film can't produce holes. Because PVC heat-shrinkable printed films are often suitable for outdoor use, it is necessary to add UV-resistant agents.

Packaging principle of PVC heat shrinkable printing film;

In the production process, when the film is stretched at a temperature above its softening point and below its melting point, the molecules are aligned, when the film is cooled sharply, the molecules are "frozen", and when the film is reheated to the stretched temperature, stress relaxation occurs, that is, the oriented molecules are de-oriented, which causes the film to shrink. When the orientation degree is high, the thermal shrinkage rate is high, while the orientation degree is low.

The PVC heat-shrinkable printing film packaging machine can be processed and cut at will. It is often used in molds, hydraulic presses, and other parts that need heat insulation. It can also be used for self-made roofs and other parts that need heat insulation. Save energy, reduce heating time, reduce heat conduction to equipment, and have good heat insulation effect.

PVC heat shrinkable printing film is used for the sales and transportation of various products, and its main function is to stabilize, cover and protect the products. PVC heat shrinkable printing film has good puncture resistance, good shrinkage and corresponding shrinkage stress.

Characteristics of PVC heat shrinkable printing film;

1. Non-shedding: the viscosity is 1% higher than that of general enterprise products, and the protective film will not fall off when attached.

2, no residue: tear off the protective film, there will be no residual text or glue.

3. Recycling: The winding film can be recycled and granulated in the factory by using general recycling equipment. It can not only reduce environmental pollution, but also save the cost of recycling packaging.

4. Non-retraction: environmental temperature difference, surface stretching, resulting in protrusion at both ends. The protective film is made of good quality material. At high temperature, we don't compare it for a while, but look at the long-term quality.

5. Reduce the overall packaging cost: replacing the traditional stretch wrapped film with film has obviously reduced the total amount of use, so its use cost, transportation cost and storage space cost have all decreased.

6. It is convenient to use and the working speed is not bad: due to the winding film, it is pre-stretched, which is quite labor-saving, and the unused packaging machine and the used packaging site can be operated by men, women and children. Under the same weight, the length of each roll of this kind of wound film is more than twice as long as that of ordinary wound film, which can reduce the frequency of replacing film rolls during packaging and save costs in transportation, packaging and distribution.

7, no degumming: use glue material, do not let the protective film become a burden that affects product quality.