How to use PVC heat shrink film

2025-06-04 10:05When using PVC heat shrink film, you need to pay attention to the following aspects:

一、Temperature control

Heating temperature: The heating temperature of PVC heat shrink film should be within its specified range. Usually, the heat shrink temperature of the product is 85±2℃, and the heat shrink time is 1~2 seconds. Too high or insufficient heating temperature will lead to poor shrinkage effect and may even damage the packaged object.

Storage temperature: PVC heat shrink filmshould be stored in a warehouse with a temperature below 30℃ (maximum below 25℃) and a humidity of 45%~75%, avoiding direct sunlight and high temperature environment. At the same time, the product should be at least 1 meter away from the heat source to prevent cracking or shrinkage deformation damage.

二、environmental conditions

Dryness and cleanliness: The processing environment should be kept dry, clean and well ventilated to prevent dust and other impurities from contaminating the surface of the material and affecting the packaging effect.

Avoid heavy pressure and impact: During storage and transportation, the PVC heat shrink film should be protected from heavy pressure and impact to prevent damage.

三、Select specifications

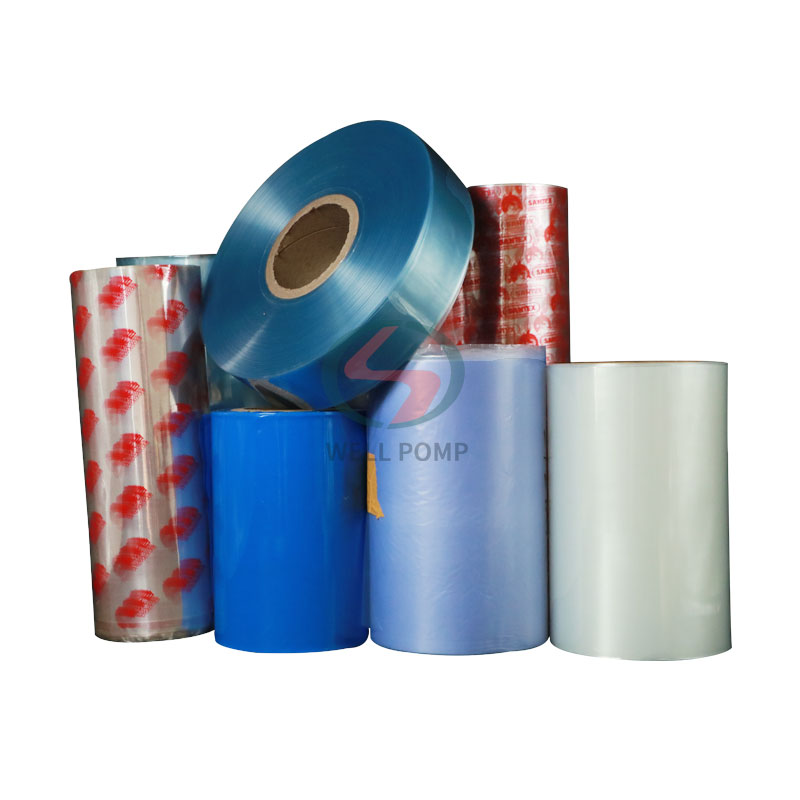

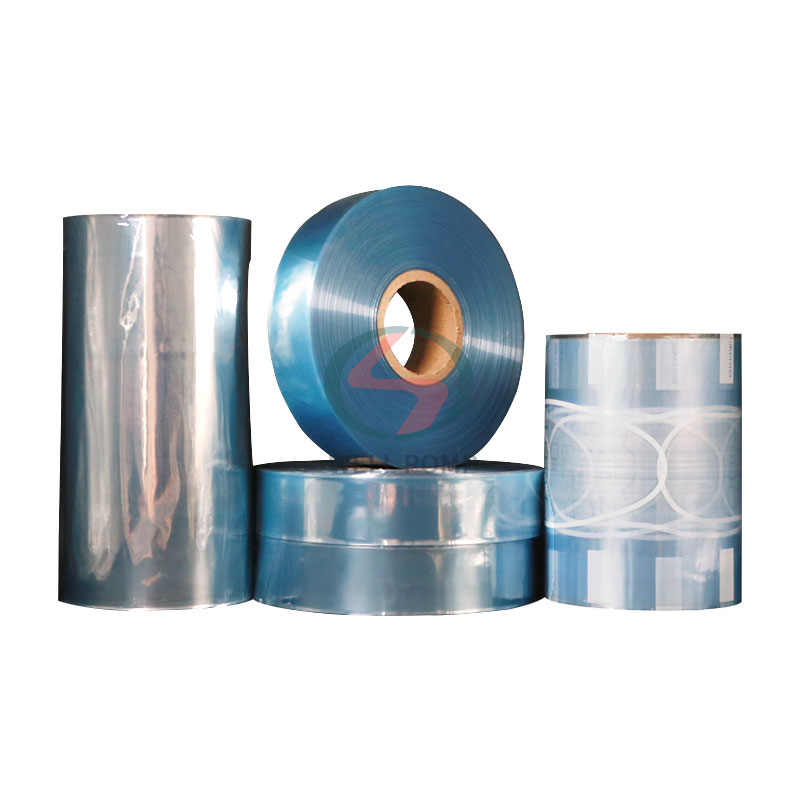

Thickness and specifications: According to the size and shape of the packaged items, choose the appropriate PVC heat shrink film thickness and specifications. Thicker films can provide better protection, but will also increase costs and packaging difficulties.

Applicable scenarios: PVC heat shrink film is suitable for packaging of various commodities, but the requirements in different scenarios may be different. Therefore, it is necessary to consider the specific application scenarios and requirements when choosing.