Characteristics of processing and molding and thermosetting plastics in heat shrinkable film

2024-01-19 11:38Heat shrinkable film can be processed into flat pocket, arc-shaped bags, trapezoidal bags, three-dimensional bags and other special-shaped bags.

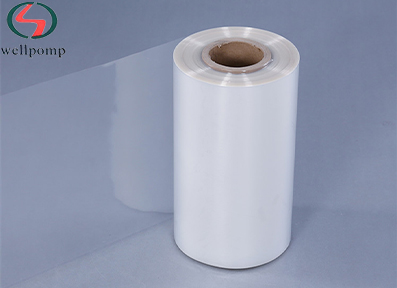

Heat shrinkable film is used for the sale and transportation of various products, and its main function is to stabilize, cover and protect products. Heat shrinkable film needs to have good puncture resistance, good shrinkage and corresponding shrinkage stress. In the process of shrinkage, the film cannot produce holes. Because heat shrinkable film is often used outdoors, it is necessary to add UV-resistant agent.

Heat shrinkable film is a kind of film material which is widely used at present. Its price is not high, the temperature shrinkage range is large, and the requirements for heat sources are not high. The main processing heat sources are hot air, infrared rays or their combination. However, PVC is difficult to recycle, and toxic gas is produced when burning, which is not conducive to environmental protection. The shrinkage rate is large, and the articles can be tightly wrapped after thermal shrinkage. If the PE straight-through bag (with openings at both ends) is made after thermal shrinkage, the articles can be lifted at both ends of the opening, which can bear the weight of 15KG and is convenient to carry.

Characteristics of thermosetting plastics produced in heat shrinkable film;

1. The material can be made of all kinds of suitable fiber or rubber fillers and some toughening agents, if necessary in an earthquake. In addition, aniline modified phenolic resin, epoxy resin, polyvinyl chloride, polyamide and polyvinyl acetal can also be used to meet the requirements of different uses. Phenolic laminate can also be made of phenolic resin, which has the characteristics of good mechanical and electrical properties, corrosion and easy processing, and is widely used in low-voltage electrical equipment.

2. Amino heat shrinkable film includes urea formaldehyde, melamine formaldehyde and urea melamine formaldehyde. They have the advantages of hard texture, scratch resistance, colorless and translucent, and colored materials can be made into colorful products, commonly known as electric jade. Because it is not afraid of oil, weak alkali and solvent (but not acid), it has good acid resistance.

It is widely used in the outer packaging of various products, such as food, tableware, cultural and sports supplies, craft gifts, printed matter, hardware and plastic products, telephones, electronic appliances, etc. It can not only achieve the functions of dustproof, touch-proof and transparent display of goods, but also increase the attractiveness of products, and can also be used to replace various cartons, which not only saves packaging costs, but also conforms to the packaging trend.

Heat shrinkable film is a kind of packaging used for all kinds of products, which plays an important role in stabilizing, covering and protecting products, and has an important influence on the sales and transportation of products. Shrinking film has good wear resistance and shrinkage, and it is close to the appearance of products in the process of shrinking packaging, which is beautiful and convenient.

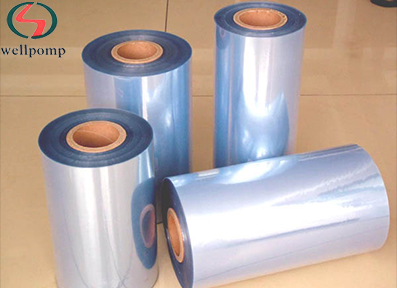

There are many classifications in heat shrinkable film, including POF heat shrinkable film, PVC shrink film, PE shrink film, etc. Different types of shrink films have different characteristics, which are reflected in the following three points:

1. PVC film. It has the characteristics of good transparency and luster.

2. POF heat shrinkable film is a kind of packaging film with high surface gloss, good flexibility, low carbon, environmental protection and wide applicability. With the application of POF heat shrinkable film process, POF heat shrinkable film has gradually replaced other films and become a mainstream packaging film.

3. PE shrink film: It has excellent flexibility, tear resistance and large shrinkage rate, and is suitable for alcohol, mineral water, various beverages and so on.

Shrinkage film can present more and more beautiful effects and stronger functions. With the improvement of quality of life and the diversification of packaging films, the requirements for shrinkage film are getting higher and higher. heat shrinkable film is used for the sales and transportation of various products, and its main function is to stabilize, cover and protect products.

Shrinkage film needs to have good puncture resistance, good shrinkage and corresponding shrinkage stress. In the process of shrinkage, the film cannot produce holes. Since the shrink film is often suitable for outdoor use, it is necessary to add UV anti-ultraviolet agent. It has good flexibility, not easy to be damaged, strong blasting resistance, good impact resistance, good tear resistance and strong tensile force, and can replace box packaging. The shrinkage rate is large, and the articles can be tightly wrapped after thermal shrinkage. If the PE straight-through bag (with openings at both ends) is made after thermal shrinkage, the articles can be lifted at both ends of the opening, which can bear the weight of 15KG and is convenient to carry. Good transparency, light transmittance of 80%, can display products, can promote products invisibly, and also reduce distribution errors in logistics links. Not afraid of water and dust, it can not only achieve packaging effect, but also beautify and protect products.